Parts washers catalog K LINE

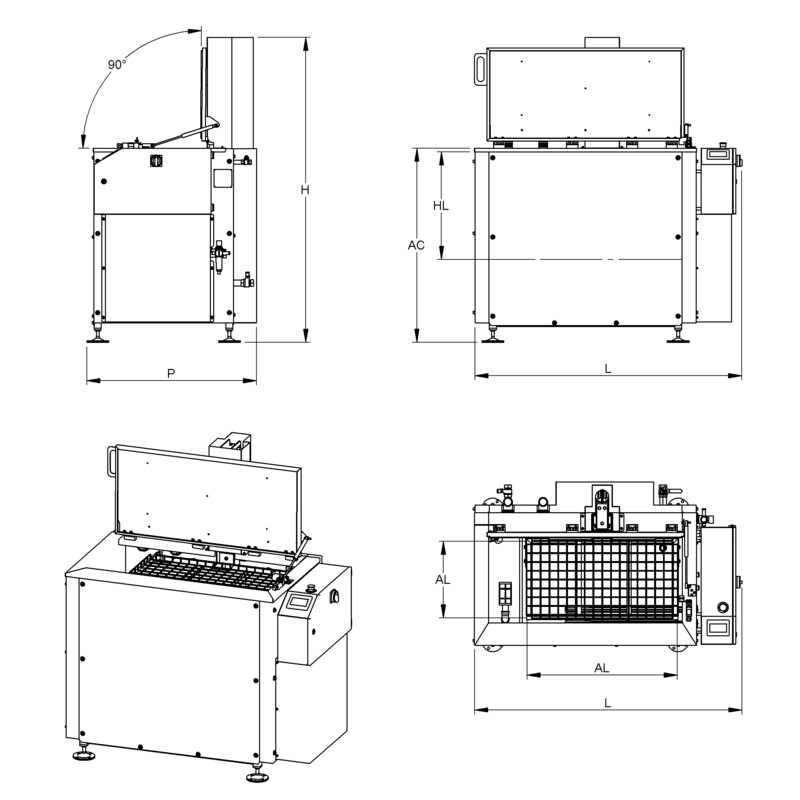

| Useful washing sizes (cm) | ultrasonic power | washing tank | tank capacity | |

| k100 | 64 x 34 x H34 | 1 kW | 100 lt | 180 lt |

|---|---|---|---|---|

| k200 | 88 x 47 x H38 | 2 kW | 200 lt | 250 lt |

| k300 | 100 x 55 x H45 | 3 kW | 300 lt | 520 lt |

| k500 | 120 x 65 x H55 | 4 kW | 500 lt | 700 lt |

Ultrasonic parts washers for heavy use

The ultrasonic washing system by teknox has been designed for a heavy and continuous use due to its high quality materials and to the most innovative technology.

The ultrasonic washing is carried out by a generator and plate transducers submerged in the liquid, placed in the front and back side.Standard machines include an automatic mobile stainless steel platform for high loading capacity, an additional tank for oil-trimming collection and a circulating pump.

- PLC with color Touch Screen

- Industry 4.0 option

- Unique tank

- Car/motorcycle maintenance

- Truck maintenance

- Railway, naval, aeronautical maintenance

- Mould washing

- Mechanical engineering, chip removal, foundries, moulding

- Surface treatment, pre-painting, paint stripping

- Aeronautical / Space Industry

- Electronic

- Chemical, Pharmaceutical, Medical, Cosmetic, Food

- Printing and colour industry

Video

K-series parts washers help you to wash parts in immersion with ultrasonic equipment. The machines consist of a main tank with the detergent water-based solution. The platform where parts are placed is automatically immersed in the liquid and all the surface is entirely washed through the ultrasonic action. The automatic washing process is set by a touchscreen display and operator is free to work on other tasks. Once the cycle is finished the platform surfaces and operators can remove the cleaned and degreased parts. An additional tank is equipped for the oils removal through the action of a circulation pump. A filter enables then the liquid filtering to remove small solid residues.

- Hatch closure assisted with gas springs and fastening hook K

- Thermal tank insulation with Aisi 430 stainless steel panels

- Siemens® electric power parts

- 4” color touchscreen display for settings and programs

- Aisi 304 stainless steel filter in pump intake

- Structure and sheet metal in contact with liquid in Aisi 304 stainless steel

- Minimum level switch

- Safety limit switch on cover opening

- Automatic lift and immersion platform

- Adjustable feet

- Recycle pump for filtration and removal of oil by overflow

- Compressed air blowing gun

- Weekly programming to start heating and deoiler (if installed)

- IP65 electrical system, management via PLC touchscreen (DGT V4)

- Heating of the liquid with stainless steel electric heating element

- Internal welding bleaching

- Stainless steel submersible ultrasound generator and transducers

- Drain valves for emptying tanks

- Manual water filling valve

- Maximum liquid level control in tank 1 and filling solenoid valve

- Pneumatic cover opening and closing with two-hand safety control unit

- Automatic liquid detergent dispenser, installed in bath 1

- Stainless steel cartridge filter (10/25/50 micron)

- Device for remote connection and remote support for HMI Weintek

- Kit for Industry 4. 0 for HMI Weintek

- Kit for use with abrasive contaminants in the washing liquid

- Stainless steel fittings and valves kit (for parts that are in contact with liquids)

- PLC Siemens® S7 1200 - HMI touchscreen Weintek

- Interface with the loading and unloading system (robot)

- Heating with external heating elements, not in contact with the liquid

- Machine equipped with wheels for handling

- Tanks emptying pump (2)

- Signal tower for indicating system status