Parts washers catalog LINEA SIMPLEX

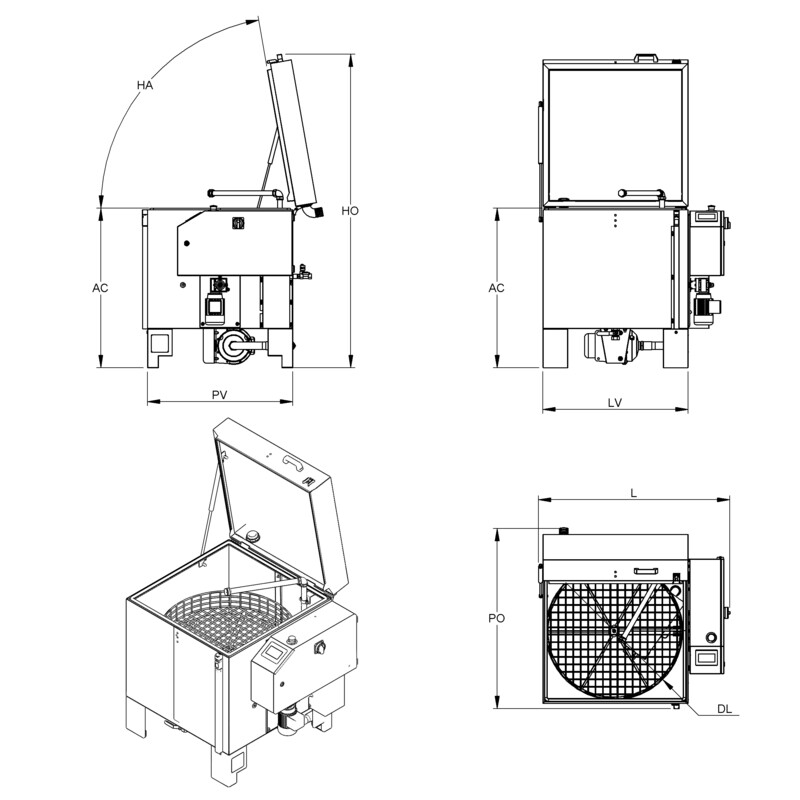

| Washing capacity ( Ø x H ) | Basket load capacity | Tank | |

| Simplex 80 | Ø 78 x H 43 cm | 100 Kg | 130 lt |

|---|

Parts washers with rotary basket, plc and touchscreen

Simplex performs the successful automatic washing of medium and large size mechanical parts.

Washing is carried out by the action of upper, lower and side nozzles. The slow rotation of the platform is ensured by a gear motor with a torque limiter. A PLC management enables numberless customisations thanks to a wide range of accessories.

- LT (heating up to 60° C)

- HT (heating up to 80° C)

- PLC with color Touch Screen

- Unique tank

- Truck maintenance

- Railway, naval, aeronautical maintenance

- Mechanical engineering, chip removal, foundries, moulding

Simplex 80 parts washers are designed for small and medium sized parts washing.

Operators insert parts in the basket, close the cover and start the automatic process.

Operators can tackle other tasks.

A gear motor slowly turns the basket and the pump starts the liquid intake from the tank and sprays it with pressure over the parts throughout by washing pipes located in the higher, lower and side parts.

The washing liquid consists of water mixed with specific eco-friendly soaps.

On the switchboard can be set all machine parameters (temperatures, heating starting and washing times) through a colour touchscreen display, and checked the washing status-flow, as well as monitored the machine alarms and warnings.

Simplex parts washer can be equipped with a large number of accessories for an integrated process such as compressed-air blowing, bag filters, high pressure pump, steam extraction, tank emptying pump and many others.

- Basket in drawn sheet metal with external border in Aisi 304 stainless steel

- Reinforced basket in electrically welded mesh with external border in galvanized steel

- Hatch closure assisted with gas springs and fastening hook

- Siemens® electric power parts

- 4” color touchscreen display for settings and programs

- Aisi 304 stainless steel filter in pump intake

- Tank border gasket

- Structure and sheet metal in contact with liquid in Aisi 304 stainless steel

- Minimum level switch

- Safety limit switch on cover opening

- Stainless steel electric pump with special seals

- Weekly programming to start heating and deoiler (if installed)

- IP65 electrical system, management via PLC touchscreen (DGT V4)

- Heating of the liquid with stainless steel electric heating element

- Mechanical rotation of basket via gearmotor

- Internal welding bleaching

- Intake and delivery pump hose (easy maintenance)

- Aisi 304 stainless steel washing pipelines with professional stainless steel flat nozzles

- Drain valves for emptying tanks

- Manual water filling valve

HT VERSION

- Electric vapour extraction

- Heat insulation with Aisi 430 stainless steel panels

- Safety limit switch with cover opening lock during cycles

- Panels under basket with grease and solids collection sump filters

- Maximum liquid level control in tank 1 and filling solenoid valve

- Compressed air blowing [B]

- Hot air drying with resistor and air blade side channel blower [B]

- Electric timed steam extraction [A]

- Basket in stainless steel Aisi 304

- Centrifugal steam condenser S mobile version [D]

- Automatic liquid detergent dispenser, installed in bath 1

- Disc oil separator integrated into basket rotation

- Bag filter in stainless steel, installed in the bath 1

- Magnetic spark plug for bag filter for ferrite powder

- Device for remote connection and remote support for HMI Weintek

- Kit for Industry 4.0 for HMI Weintek

- Kit for use with abrasive contaminants in the washing liquid

- Stainless steel fittings and valves kit ( for parts that are in contact with liquids)

- PLC Siemens® S7 1200 - HMI touchscreen Weintek

- High pressure washing pump

- Panels under the basket with cap filter for collecting grease and chips

- Stainless steel Aisi 304 retention tank with drip-catcher

- Upper ramp fastened to the cover

- Nebulized rinse from water mains, draining into the washing tank

- Machine equipped with wheels for handling

- Emptying pump

- Signal tower for indicating system status

- Pipes with blade-nozzle in stainless steel 1/8"

ACCESSORIES NOTES LEGEND

A: vapour extraction is included in the HT version

B: panels under the basket are mandatory (if in the price list for that model)

D: vapour extraction is mandatory (if in the price list for that model)

Paint stripping on ultrasonic parts washer

Find out how a cast iron pump manufacturer solved the need for paint stripping on its paint tools without the use of solvents, flammable products or volatile organic compounds (VOCs).

Mold washers in brick production

Find out how a cast iron pump manufacturer solved the need for paint stripping of its paint tools without the use of solvents, flammable products or volatile organic compounds (VOCs).