Parts washers catalog BOOSTER LINE

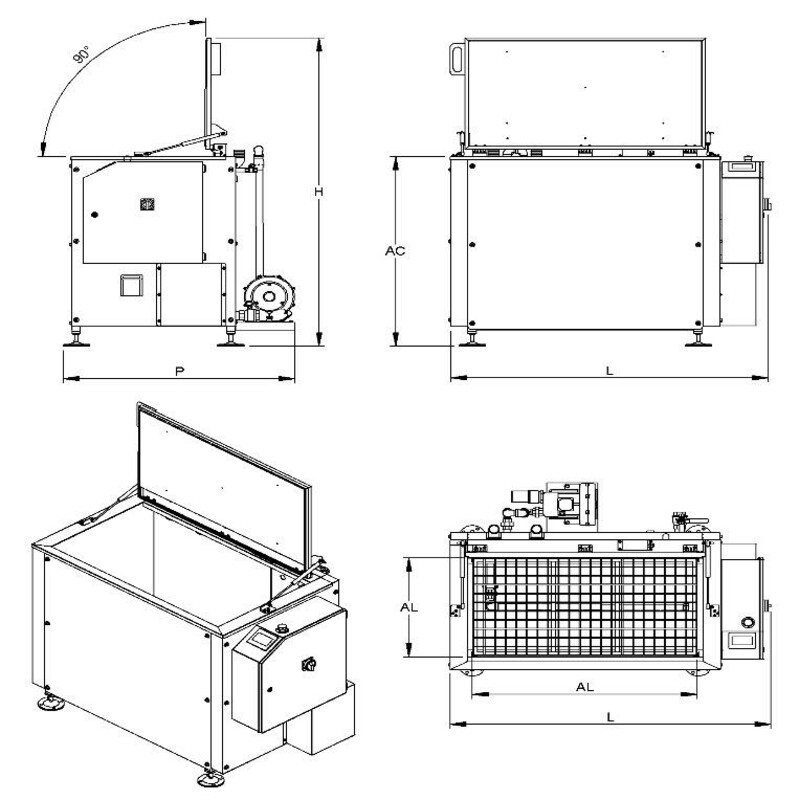

| Dimensions and layout | BS_100 | BS_200 | BS_300 | BS_500 |

| Depth (P) | 80 cm | 90 cm | 100 cm | 110 cm |

| Height (H) | 175 cm | 175 cm | 200 cm | 200 cm |

| Loading height (AC) | 100 cm | 100 cm | 100 cm | 100 cm |

| Noise HT (RU_HT) | 70 dBa | 70 dBa | 70 dBa | 70 dBa |

| Washing height (HL) | 40 cm | 40 cm | 45 cm | 45 cm |

| Opening angle (HA) | 90° | 90° | 90° | 90° |

| Washing area (AL) | 65 x 35 cm | 85 x 45 cm | 105 x 55 cm | 125 x 65 cm |

| Width (L) | 110 cm | 130 cm | 150 cm | 170 cm |

| Weight (W) | 150 kg | 200 kg | 300 kg | 400 kg |

Washing system with air agitation

The Teknox Booster treatment plant allows you to perform the immersion treatment of medium and large parts and weights.

Thanks to the flow of air introduced into the liquid, a hydrokinetic effect of movement is created which helps and accelerates the chemical process of the bath.

Widely used for paint stripping and degreasing of parts. The machine is available in HT version ( insulated, maximum and adjustable temperature up to 80°C).

- HT (heating up to 80° C)

- PLC with color Touch Screen

- Industry 4.0 option

- Unique tank

- Car/motorcycle maintenance

- Truck maintenance

- Railway, naval, aeronautical maintenance

- Mould washing

- Mechanical engineering, chip removal, foundries, moulding

- Surface treatment, pre-painting, paint stripping

- Aeronautical / Space Industry

- Electronic

- Chemical, Pharmaceutical, Medical, Cosmetic, Food

- Printing and colour industry

- Additive manufacturing

Teknox's Booster is an immersion treatment system that is ideal for medium- to large-sized and heavy workpieces. A flow of air within the liquid generates a hydrokinetic effect, optimizing and speeding up the chemical bath process. It is used extensively in paint stripping and degreasing of components. The insulated HT (High Temperature) version allows temperatures up to 80°C.

- "Booster" electric air turbulence generator

- Door closure assisted with gas springs and fastening hook

- Drain valves for emptying tanks

- Heating with external resistances, not in contact with the liquid

- HT Version

- Internal ed external welding bleaching

- IP55 main electrical box, management with touchscreen PLC (DGT V4)

- Manual water filling valve

- Minimum level switch

- Piece support grid at the bottom made of stainless steel

- Siemens electric power parts

- Structure and sheet metal in contact with liquid in AISI 304L stainless steel

- Thermal tank insulation

- Automatic chemical product dispenser, installed in bath 1

- Automatic lifting and dipping platform with two-hand control

- Compact pneumatic oil separator

- Detergent suction tank for automatic dispenser

- Device for remote connection and remote support for PLC Siemens

- Device remote connection and remote support for HMI Weintek

- Emptying pump

- External pneumatic oil separator with stainless steel floats

- HMI Siemens KTP - Display (only for Siemens PLC)

- Industry 5.0 Ready (Energy Meter)

- Kit for Industry 4.0 for HMI Weintek

- Kit for Industry 4.0 for PLC Siemens

- Maximum liquid level control in tank 1 and filling solenoid valve

- PLC Siemens S7 1200 - HMI touchscreen Weintek

- Stainless steel AISI 304L retention tank with drip-catcher [D]

- Stainless steel fittings and valves kit ( for parts that are in contact with liquids)