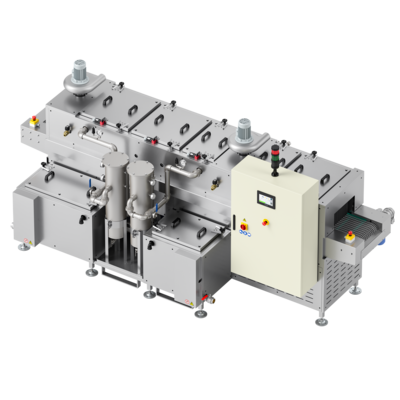

Parts washers catalog ROUNJET LINE

| Portata di Carico | Capacità Serbatoio | |

| RNDJ 1000 | 60 kg | 400 lt |

|---|---|---|

| RNDJ 1200 | 60 kg | 500 lt |

| RNDJ 1400 | 60 kg | 600 lt |

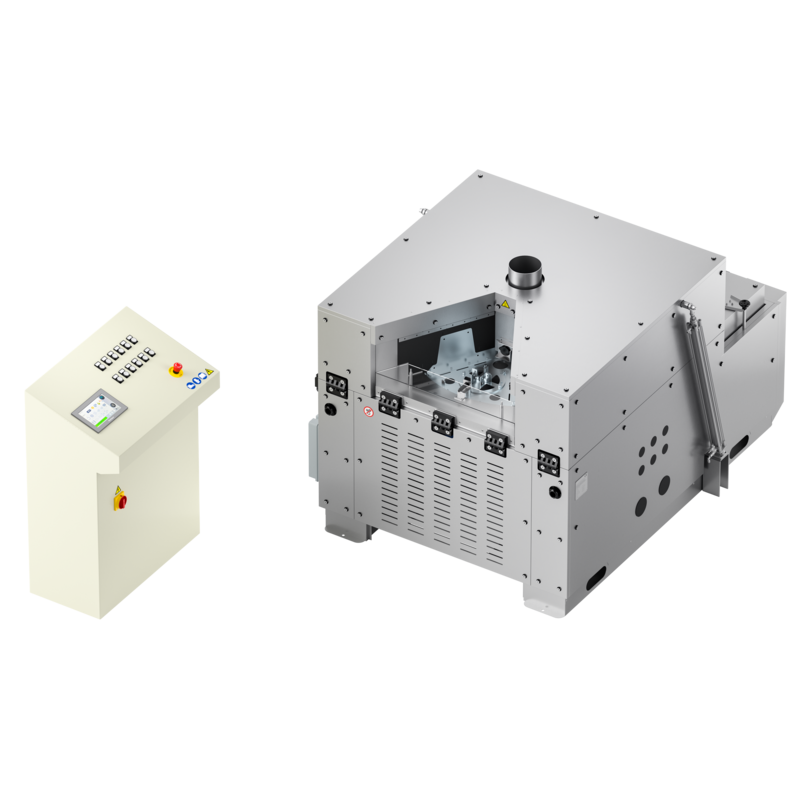

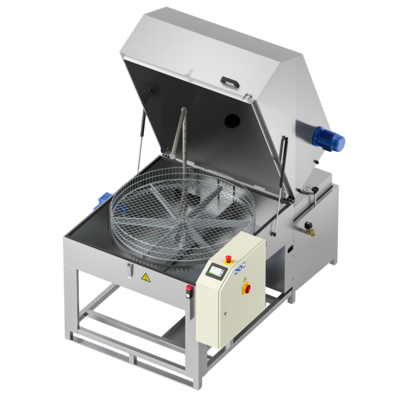

Turntable parts washer for small and medium sized parts and low cycle time

Roundjet is a rotating table parts washer (transfert type) that enables the washing of small size mechanical parts in a very quick time.

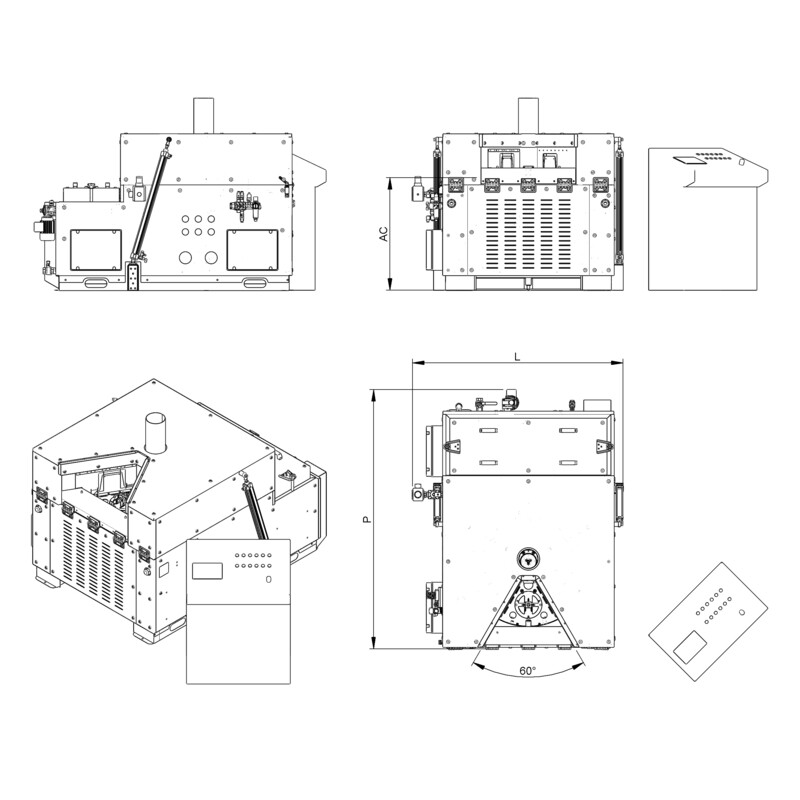

The loading platform is divided into 6 areas: loading, extraction, washing, pause, blowing and hot drying.

By the loading station (the only one “opened”), the table step-by-step rotation enables parts going through all treatment phases up to when parts returned to the initial position for loading operations.

It is possible to use the same machine to wash similar parts thanks to the interchangeability of the positioning supports.

A PLC management enables numberless customisations thanks to a wide range of accessories.

It is notably ideal for operations in robotised isles (positioning precision by +/- 0.5 mm). It can be also realised, on demand, for being used by operators with manual loading and unloading.

- HT (heating up to 80° C)

- PLC with color Touch Screen

- Industry 4.0 option

- Unique tank

- Mechanical engineering, chip removal, foundries, moulding

- Surface treatment, pre-painting, paint stripping

- Aeronautical / Space Industry

- Electronic

- Chemical, Pharmaceutical, Medical, Cosmetic, Food

Video

Roundjet parts washer is a step-by-step washing machine on a similar "rotating table" system.

The parts washer consists of: loading/unloading, steam extraction, washing, unloading, compressed air blowing, and hot-air drying.

The rotating table is made up of 6 identical sections each of them having a parts holder in stainless steel and in anti-scratching material.

Roundjet parts washer allows a single parts type to meet the needs of a single parts position for the washing.

However it is possible to wash different parts shapes if the redesigning of the six sections is planned during the project design phase.

It is especially suitable for robotic isles with parts loading and unloading directly by an anthropomorphic robots (positioning accuracy by +/- 0.5 mm).

It can be also designed for manual loading and unloading operations.

- Safety photocell barrier

- Siemens® electric power parts

- 7” color touchscreen display for settings and programs

- Box filter made up of 6 Aisi 304 SS vertical filters for pre-filtration of the liquid flowing back into the tank

- Aisi 304 stainless steel filter in pump intake

- Structure and sheet metal in contact with liquid in Aisi 304 stainless steel

- Minimum level switch

- Pressure gauge for control of pressure delivered

- Template for positioning piece/s

- Safety limit switch on door opening

- Stainless steel electric pump with special seals

- Weekly programming to start heating and deoiler (if installed)

- IP65 electrical system, management via PLC touchscreen (DGT V4)

- Separate remote-controlled electric cabinet

- Heating of the liquid with stainless steel electric heating element

- Internal welding bleaching

- Tanks accessible from the outside

- Stainless steel bottom section load-bearing structure

- Aisi 304 stainless steel washing pipelines with professional stainless steel flat nozzles

- Drain valves for emptying tanks

- Manual water filling valve

- Maximum liquid level control in tank 1 and filling solenoid valve

- Demineralizer with mixed resins and conductivity meter

- Loading/unloading area photocell barrier system

- Centrifugal steam condenser S mobile version [D]

- Automatic liquid detergent dispenser, installed in bath 1

- External pneumatic oil separator

- Bag filter in stainless steel, installed in the bath 1

- Magnetic spark plug for bag filter for ferrite powder

- Device for remote connection and remote support for HMI Weintek

- Kit for Industry 4.0 for HMI Weintek

- Kit for use with abrasive contaminants in the washing liquid

- PLC Siemens® S7 1200 - HMI touchscreen Weintek

- High pressure washing pump

- Interface with the loading and unloading system (robot)

- Stainless steel Aisi 304 retention tank with drip-catcher

- Parts presence/absence sensors

- Emptying pump

- Signal tower for indicating system status

- Workpieces positioning /clamping pallet