Metal washing systems for CNC machining

In the CNC machining sector, cleaning parts is an essential step to ensure quality, precision, and reliability. After turning, milling, or drilling operations, components are often contaminated with oils, chips, and metallic residues which, if not properly removed, may compromise subsequent assembly, treatment, or testing phases.

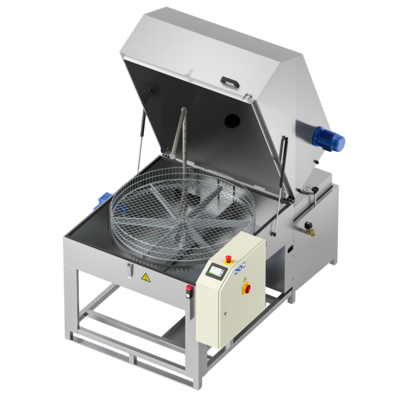

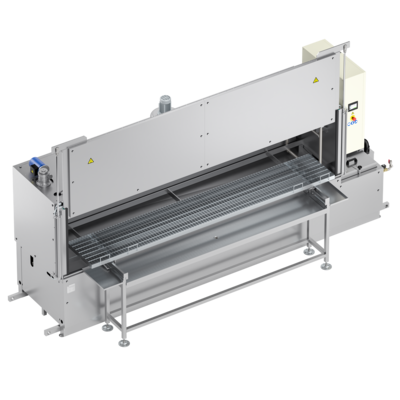

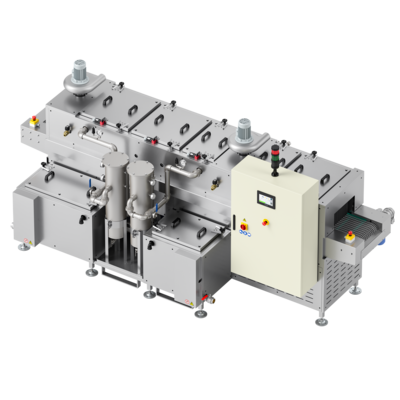

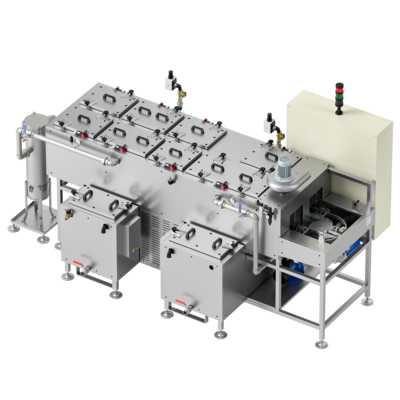

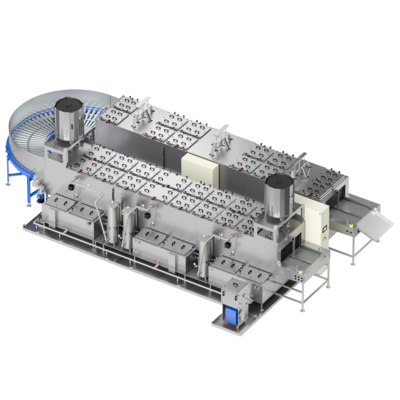

Teknox metal washing systems are designed to meet the needs of mechanical workshops and companies operating in the precision engineering sector, ensuring deep and uniform cleaning of machined components.

Effective solutions for every type of part

Teknox designs industrial washing systems suitable for parts of any shape, size, and material. The systems can be configured to remove contaminants from both raw and finished components, even with complex geometries.

Among the technologies used:

- High-pressure spray washing, ideal for removing chips and coolants

- Ultrasonic cleaning, for deep cleaning of complex geometries

- Combined systems with integrated drying, rinsing, and blowing stages

- Hydrokinetic immersion washing, to remove surface contaminants from intricately shaped parts.

Each system is designed to meet the customer’s specific production requirements.

Integration into production processes

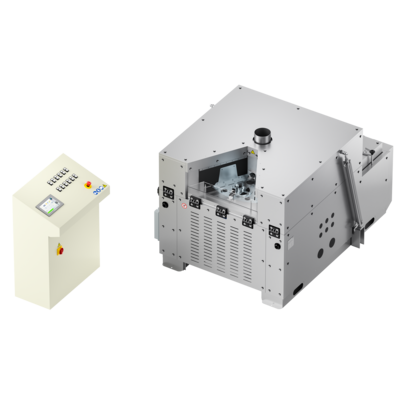

Our metal washing systems easily integrate into existing production flows, both as standalone units and as part of automated cells. Depending on requirements, systems can be configured for manual, semi-automatic, or fully automatic loading.

This allows optimization of processing times, reduction of contamination risks, and overall improvement of production line efficiency.

Safe cleaning even for delicate components

Teknox machines are compatible with a wide range of materials such as steel, aluminum, brass, and technical plastics. Thanks to the ability to set specific parameters – temperature, pressure, detergent type – effective cleaning can be achieved without damaging surfaces, machining, or critical tolerances.

Reliability and support for mechanical workshops

Choosing a Teknox system means relying on a partner with expertise in the treatment of machined parts. Each solution is tailored starting from the type of CNC machining performed by the customer, taking into account the type of contamination, quantity of parts, and required cleanliness standards.

We support each project with technical assistance, customized testing, and scheduled maintenance options, to ensure operational continuity and consistent long-term performance.