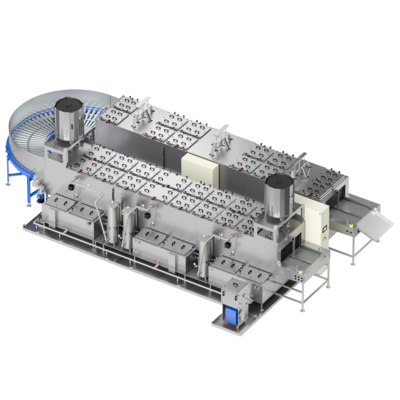

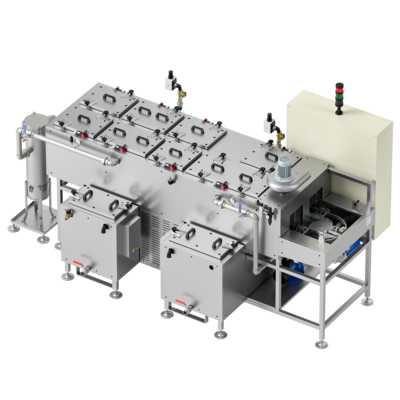

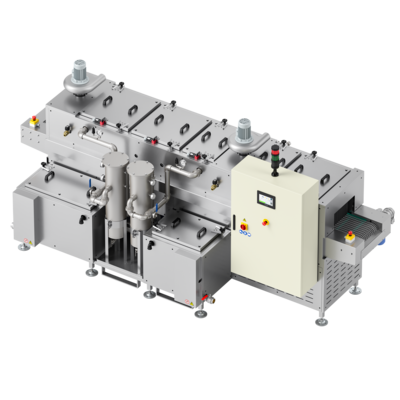

Solutions for industrial washing in the tube processing and production sector

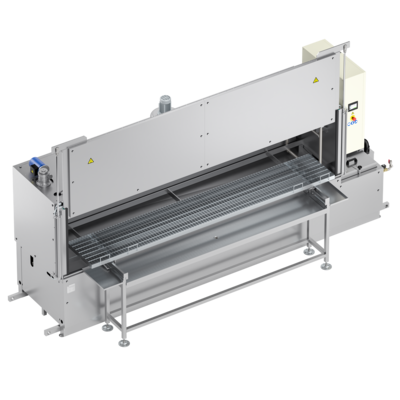

In the pipe manufacturing and processing sector, cleaning metal components is a crucial step in ensuring the final quality of the product. Residues of lubricants, chips, oxides, and dust can compromise subsequent processes such as welding, coating, bending, or testing. Teknox designs and manufactures industrial parts washing machines specifically tailored to meet the needs of this sector, delivering high performance even in the presence of complex geometries and difficult-to-reach internal surfaces.

Thorough cleaning of raw, semi-finished, and finished pipes

Teknox machines can clean pipes made of steel, copper, aluminum, and special alloys, whether raw or already subjected to mechanical processes or surface treatments. The systems are designed to effectively remove:

- Neat and emulsified oils from cutting, drawing, or rolling operations

- Metal chips and solid residues

- Dust and oxides

- Protective agents and transport-related contaminants

Thanks to customized solutions, it is possible to configure systems for internal and external cleaning of pipes, even of considerable length and small diameter, without damaging the surfaces.

Integration into production processes

Teknox parts washers can be integrated in-line with other machinery in the production process, optimizing time and reducing handling. Each machine can be customized with:

- Automated loading/unloading systems

- Tailored washing, rinsing, and drying cycles

- Liquid filtration and recirculation systems

- Hot air or vacuum drying units

Maximum energy efficiency and sustainability

Attention to energy efficiency and waste reduction is an integral part of Teknox’s production philosophy. The systems, also thanks to the presence of dedicated accessories, not only offer high performance but also significantly help to reduce operating costs and environmental impact.

Experience and dedicated technical support

With extensive know-how in the field of industrial metal cleaning, Teknox supports pipe manufacturers in selecting the most suitable solution for their specific needs. From design to commissioning, every system is managed by a dedicated technical team, ensuring customization, rapid intervention, and qualified after-sales support.