Metal cleaning systems for the electronics industry

In the electronics industry, product quality also depends on the perfect cleaning of metallic and electronic components used during production stages. Electronic boards, connectors, heat sinks, frames, and micro-components require specific washing treatments: even an invisible residue can compromise electrical conductivity or cause malfunctions.

Teknox metal washing systems safely remove contaminants such as machining oils, fluxes, solder pastes, fine dust, and oxides. This way, components are ready for subsequent assembly or soldering processes, ensuring maximum reliability of the finished product.

The challenges of cleaning in electronic processes

In the electronics sector, quality standards are extremely strict. For this reason, the washing phase is not an accessory operation, but a critical step to ensure consistent performance.

The main challenges to address include:

- Thorough cleaning of miniaturized components with complex geometries

- Removal of residues that may cause short circuits or insulation defects

- Prevention of cross-contamination in production batches

- Compliance with safety and environmental regulations

Teknox washing systems for electronics are designed to face these challenges with tailored, reliable, and replicable solutions.

Washing technologies for electronics

To meet different production needs, Teknox designs systems that combine advanced technologies, ensuring maximum delicacy and precision even on complex components.

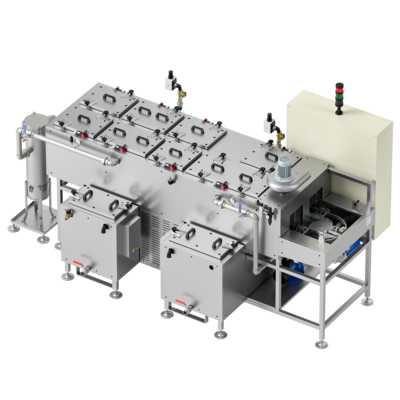

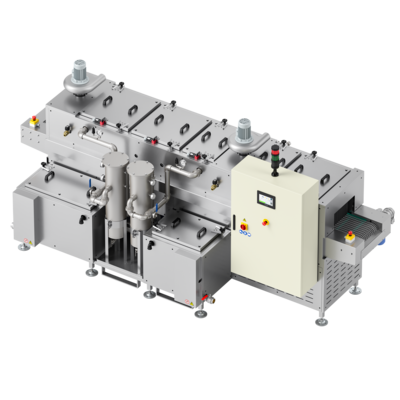

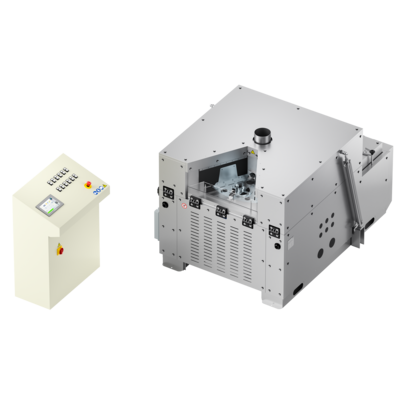

- Precision ultrasonic cleaning: ideal for electronic boards, connectors, and micro-components. Ultrasonic waves penetrate even the most difficult cavities, removing contaminants without damaging the materials.

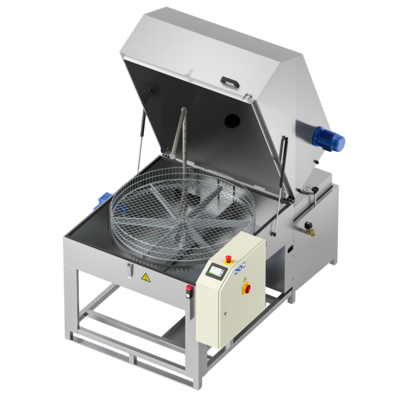

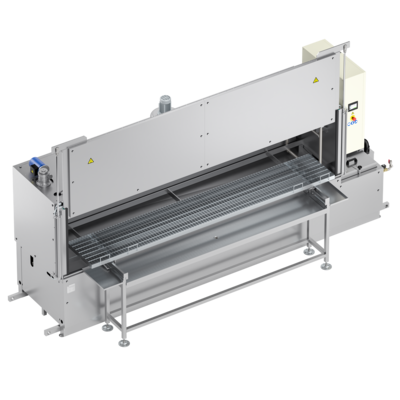

- High-pressure spray cleaning: perfect for mechanical parts, heat sinks, and metal frames, where speed and cleaning power are required.

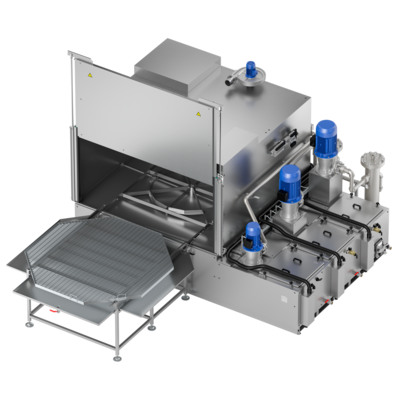

- Combined systems: integrate multiple technologies to handle different types of components in a versatile way, optimizing time and costs.

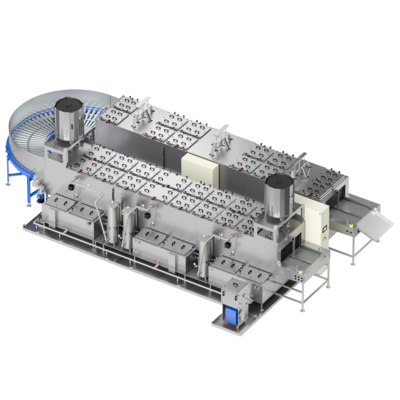

All systems can be automated and directly integrated into production lines, increasing overall efficiency.

Advantages of Teknox metal washing machines for electronics

Choosing Teknox means equipping yourself with systems designed to improve the quality and efficiency of electronic production. The main benefits include:

- Reliability of the final product: components always clean and performing.

- Reduction of waste and fewer defects in functional tests.

- Compliance with international industry standards and environmental regulations.

- Production efficiency: fast, configurable, and consistent cycles.

- Sustainability: reduced water and detergent consumption, thanks to advanced technological solutions.

Teknox, strategic partner for electronics

Each Teknox metal washing system is the result of a careful analysis of customer needs. For the electronics sector, this means developing solutions that take into account:

- Dimensions and fragility of the components to be treated

- Type of contaminants to be removed

- Need for integration with automated lines

- Productivity and sustainability goals

Thanks to consolidated experience and a customization-oriented approach, Teknox is the ideal partner for electronics companies that want to improve the quality and reliability of their products while remaining competitive in the global market.