Metal washing systems for treating parts prior to painting and paint stripping

In the pre-painting and industrial paint stripping sector, proper surface preparation of metal parts is a fundamental step to ensure the effectiveness of subsequent treatments and the quality of the finished product.

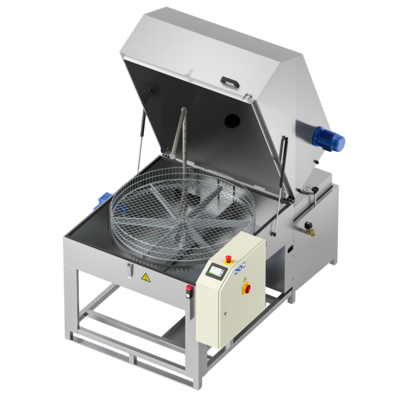

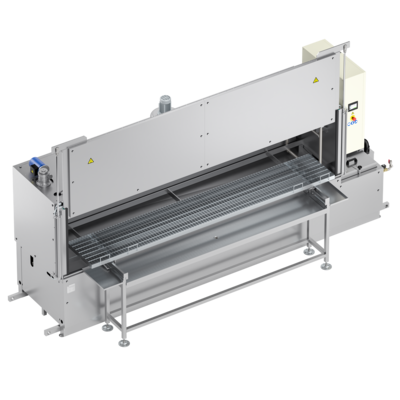

Teknox metal washing systems are designed for the washing and treatment of metal parts during the pre-painting and paint stripping phases, ensuring perfectly clean surfaces suitable for painting or reworking processes.

Thanks to advanced technological solutions, Teknox metal washing machines allow the removal of oils, greases, machining residues, and surface contaminants, effectively supporting production cycles where deep and controlled cleaning is required before painting or after coating removal.

Consistent quality in surface treatment of parts

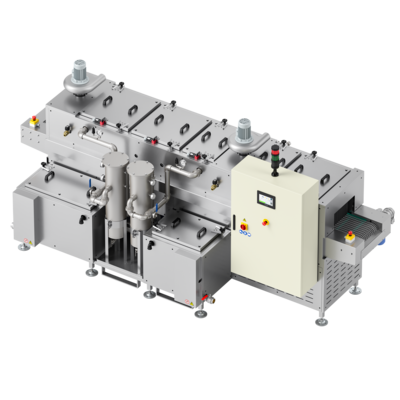

Metal washing systems dedicated to the treatment of parts in pre-painting and paint stripping guarantee high quality standards throughout the entire washing process.

Process parameter control ensures that each part is correctly prepared for subsequent stages, reducing adhesion defects and quality issues.

The result is a uniform, clean surface that complies with the requirements of modern industrial painting cycles.

Increased productivity in treatment lines

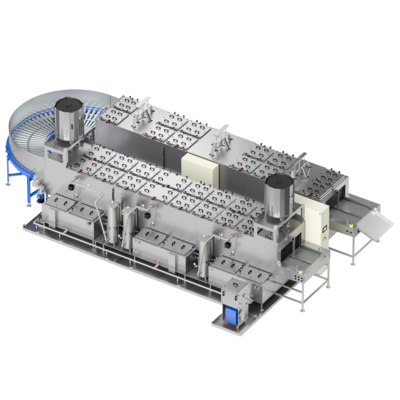

Teknox metal washing machines are designed to optimize part treatment within production lines, contributing to a significant increase in productivity.

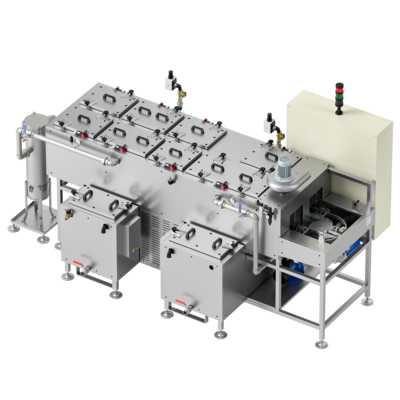

Automation of washing and rinsing cycles helps reduce downtime, improve process continuity, and manage high production volumes with consistent and repeatable results.

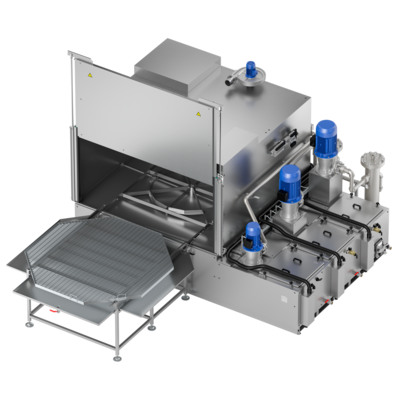

Reduced consumption and optimized operating costs

In the treatment of parts intended for pre-painting and paint stripping, process efficiency is also essential from an economic standpoint.

Teknox metal washing systems are designed to ensure optimized management of water, detergents, and energy, enabling a tangible reduction in consumption and operating costs without compromising washing quality.

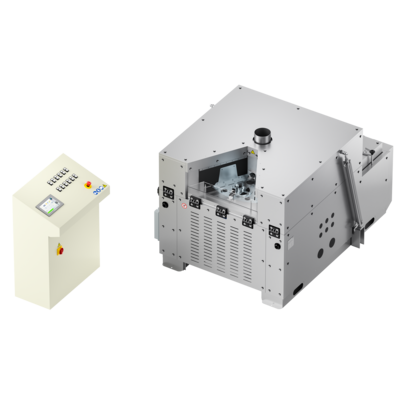

Process automation and reduced manual intervention

The high level of automation of metal washing systems significantly reduces manual intervention during part treatment phases.

This results in greater operator safety, higher process reliability, and consistent result quality, even with complex geometries or difficult-to-treat surfaces.

Improved quality of the finished product

Proper treatment of parts during the pre-painting and paint stripping phases directly affects the quality of the finished product.

The thorough cleaning achieved with Teknox metal washing systems improves coating adhesion, reduces the risk of surface defects, and helps increase the durability and commercial value of the manufactured product.

Teknox: experience and reliability in metal part treatment

Teknox specializes in the design and manufacture of industrial metal washing systems for the treatment of metal parts in various application sectors, including pre-painting and paint stripping lines.

The experience gained through the study of production processes enables the company to develop customized solutions, perfectly integrated with customer requirements.

Choosing Teknox means selecting a competent partner, capable of supporting the company at every stage of the project: from technical analysis of the treatment process, to system construction, through to after-sales support.

Established know-how, a quality-oriented approach, and continuous investment in innovation make Teknox a reliable reference for those seeking efficient, high-performance metal washing systems designed to enhance the treatment of metal parts.